Non Slip Surface For Concrete Ramp

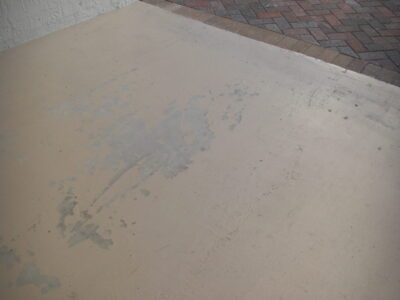

- ramp before non slip treatment

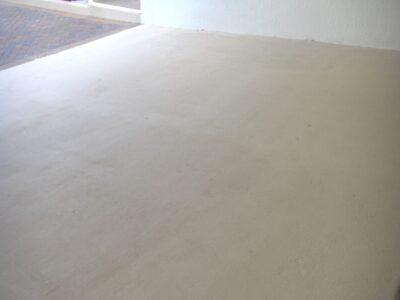

- ramp before non slip treatment 2

A pedestrian ramp was too slippery. The surface had multiple layers of stain, which began to peel, and it needed a non-slip application.

- Option 1: Chemically stripping the area would have taken a very long time due to the numerous layers of stain. The area’s borders were pavers, and there was a chance the pavers would have been etched or discolored by the aggressive chemicals being used.

- Option 2: Sandblasting the area would have made a mess and created a lot of noise. Sand blasting by itself is very loud, and this area was in between two buildings, so that the reverberation would have been tremendous and disturbing to the residents.

- Option 3: Grinding the surface by typical grinding equipment would have actually created a smoother surface. Although non-slip could be added, we wanted a more pronounced profile for the traffic coating to adhere to.

Solution: Using the latest technology, we are duplicating the results of sandblasting; however, we use water instead of sand. By utilizing water pressure up to 40K PSI, we can not only strip off layers of paint but also create a profile conducive to the adhesion of the traffic coating and a non-slip surface. This water pressure equipment is also equipped with a vacuum recovery system; therefore, the paint is removed while stripping. In addition, we have gone the extra mile and added a very aggressive non-slip additive to the traffic coating applied. This results in a very coarse, non-slip surface.

- ramp during non slip treatment

- ramp after non slip treatment 2

For additional information, go to National Sealing

LIKE us on Facebook and receive information, tips, and industry news